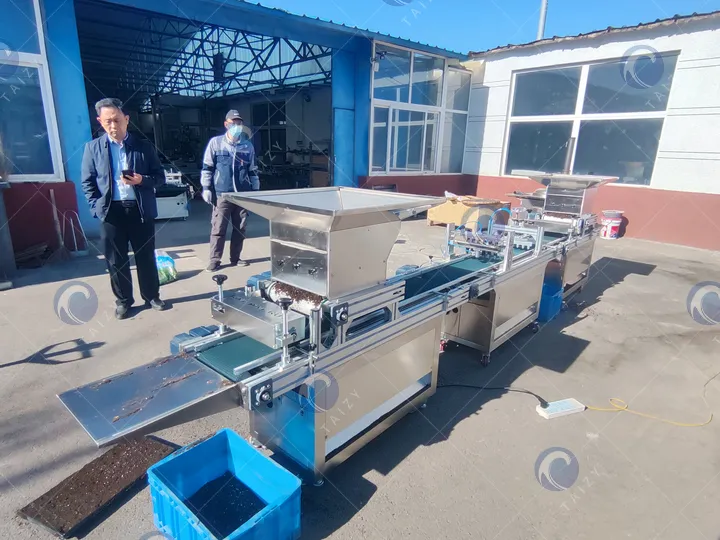

In December 2025, our Turkish customers visited our seedling equipment factory to conduct an on-site inspection of the manufacturing process and equipment performance. The primary focus of this tour was to test the KMR80-2 nursery seedling machine and determine its suitability for the client’s seeds.

There are four main points of focus, which are:

- Real manufactuerer

- Machine performance and stability

- Support customization

- Huduma ya baada ya mauzo

Key focus 1: Verify authentic manufacturing factory

During their visit, the first thing the customers wanted to confirm was whether we were a factory that independently manufactured seedling equipment.

Through on-site visits to the production workshop, assembly area, and finished product display zone, customers gained a clear understanding of the complete process, from machining and assembly to final testing, further enhancing confidence in equipment quality and delivery capability.

Key focus 2: Nursery seedling equipment performance and stability

On-site, we arranged a demonstration of the seedling machine‘s operation, highlighting its performance in hole-punching, seed sowing, and soil covering processes.

The clients paid particular attention to sowing precision, operational stability, and overall structural design, offering positive feedback on the machine’s performance during continuous operation.

Key focus 3: Customization requirements

Addressing the client’s cultivation of tomatoes, peppers, eggplants, and Ponicam, we detailed customization options for seedling trays, suction needle models, and seeding methods.

Through communication, the customers confirmed that the seedling equipment can be flexibly adjusted according to their seedling tray specifications and seed characteristics, better meeting actual seedling cultivation needs.

Key focus 4: After-sales service and spare parts support

During the tour, clients also focused on understanding our after-sales service system, including

- Equipment operation guidance

- Supply of common spare parts

- Remote technical support solutions

We provided detailed explanations on replacement procedures for wear-and-tear components of seedling machines and spare parts inventory status, alleviating clients’ concerns about post-purchase maintenance.

Full-service reception for a pleasant visit

Throughout the visit, we provided comprehensive hospitality services, including:

- Itinerary coordination

- Vehicle pick-up and drop-off

- Factory transportation

- Comprehensive technical explanations

All these ensured the clients gained efficient and thorough insights into our seedling machine capabilities and company strengths.