What is mechanical Seedling

Mechanized seedling is to use machines to raise seedlings instead of artificial ones. The machine used in this process is a seedling machine, and other auxiliary equipment includes seedling trays and seedling substrates.

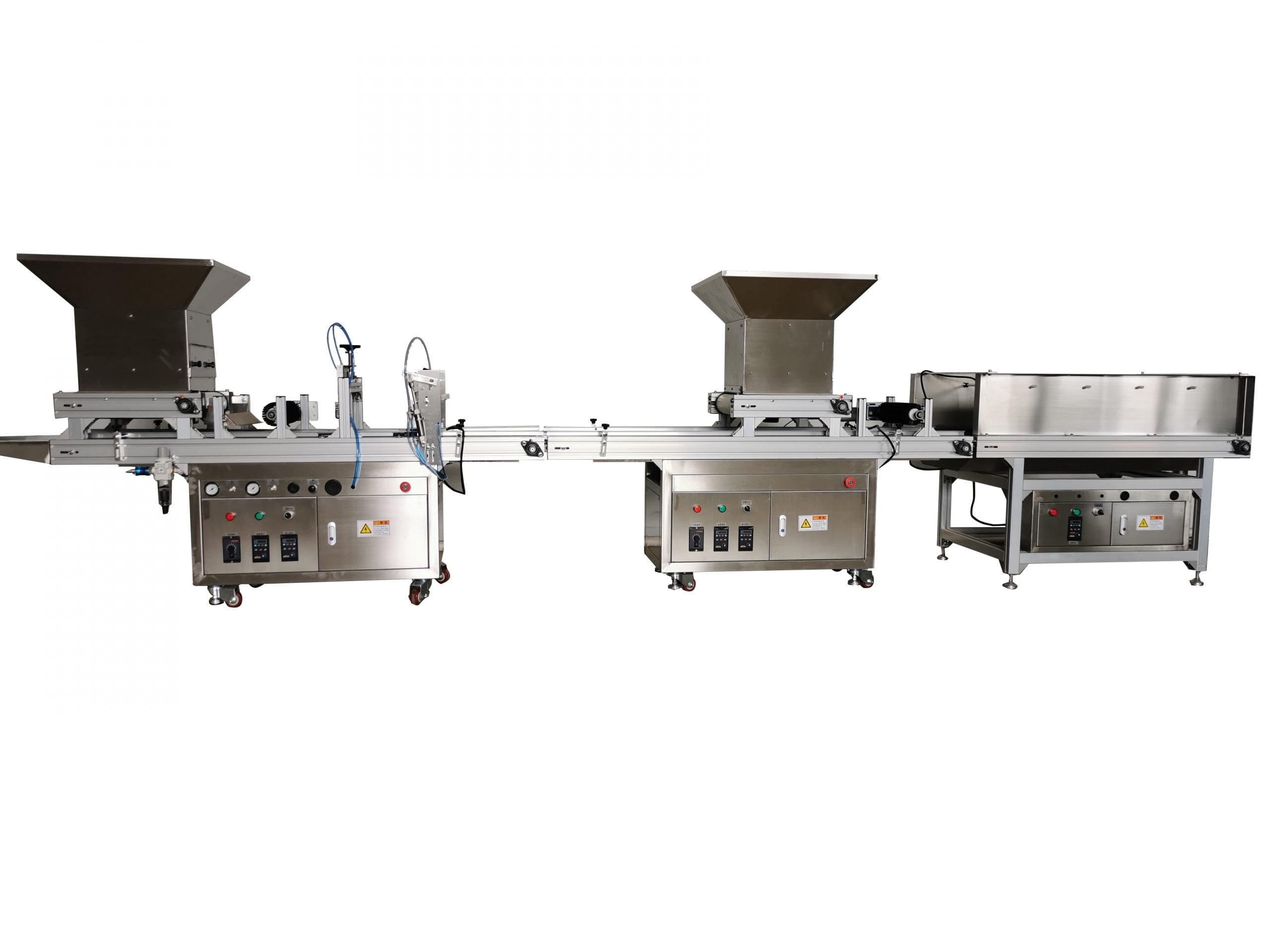

Nursery Machinery

Nursery machines are divided into automatic seedling raising machines and semi-automatic seedling raising machines, which can finish cover soil, punch holes, and plant seeds automatically.

Seedling Substrate

The substrate for growing seedlings in the soil. This is not ordinary soil. It is disinfected topsoil: organic fertilizer: organic matter according to the volume ratio of 70:27:3, and stir it evenly. Load the substrate into the seedling trays, spray the trays with rooting dispersant or spray the seedling plug with 50% carbendazim, and it is required to pour the seedling substrate thoroughly. You can also choose to purchase a special substrate for the nursery.

Mechanical Seedling Process

First, the worker puts the seedling trays on the machine, and the machine automatically spreads the substrate, then sprays water. Second, put the seeds on trays, and then spreads the second layer of the substrate, and then sprays the water. Finally, the trays can be loaded.

The seedlings cultivated in this way grow vigorously. As far as the roots of the seedlings are concerned, they are very strong. And there are a lot of hair roots. This is called a strong seedling. When plants in the field, the yield advantage will be much more obvious.

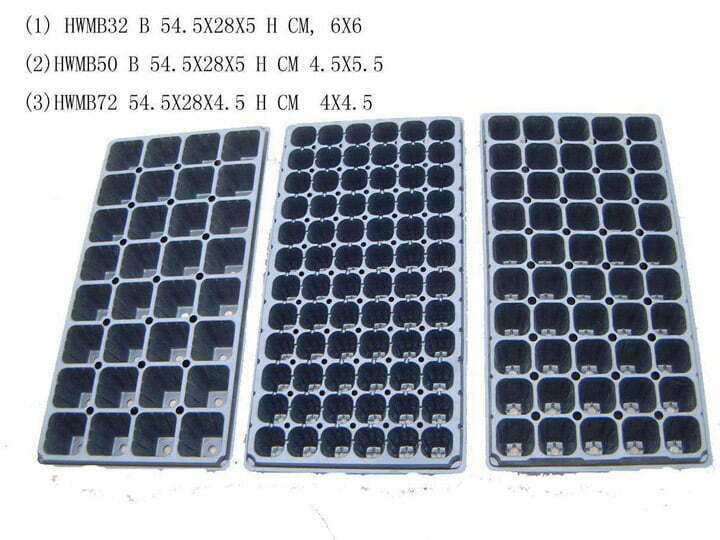

Seedling Trays Selection

For peppers, small tomatoes, and eggplants, choose 72 holes, 54×28cm floppy disks, each hole has a diameter of 3.8cm, a lower base of 2.0cm, and a hole depth of 4.6cm.

Bitter melon, pumpkin, green (yellow) melon, melon, winter melon: choose 50 holes, 54×28cm floppy disk, each hole has a diameter of 5 cm, a base diameter of 2.2 cm, and a hole depth of 5 cm.

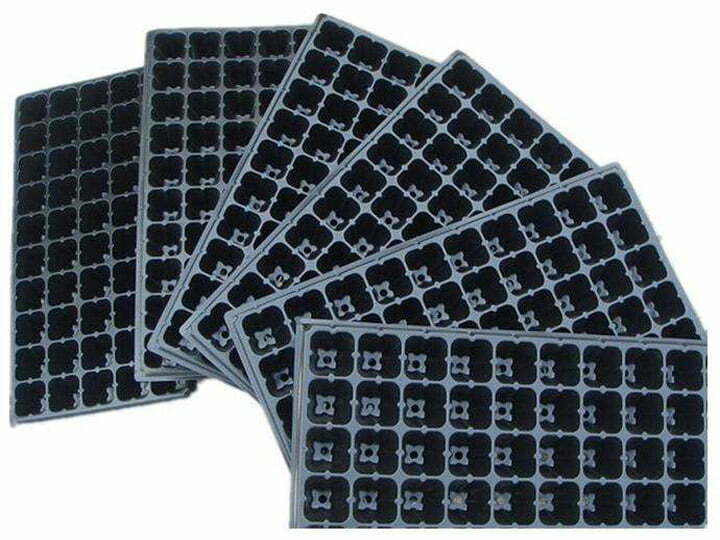

In addition, the used seedling trays may be infected with residual pathogenic bacteria and eggs, so they must be cleaned and disinfected. The method is to first remove the residual substrate in the seedling tray, rinse it with clean water, dry it, and soak it with carbendazim for 12 hours or soak it with potassium permanganate for 30 minutes. It can also be disinfected with a formaldehyde solution and bleach solution. The sterilized seedling tray must be thoroughly washed with water and dried before use.

The Importance of Mechanical Seedling

The most critical period for crop planting is the germination stage of seeds. Temperature, humidity, and wind speed will all affect the germination of seeds, and mechanized seedling cultivation can reasonably control these factors, and almost every seed can germinate.

In addition to ensuring the quality of seedlings, mechanized seedling raising can also greatly save labor. For example, 22 seedling nursery workers can produce 9,000 seedling floppy disks per day, which is equivalent to nearly 27 hectares of seedlings, and an average of 1.5 hectares per person can be cultivated per day. Compared with the traditional method of raising seedlings, efficiency is increased by more than 10 times. Production efficiency has increased, and labor expenses have been reduced accordingly.