The vegetable transplanter is mainly used for transplanting seedlings raised by nursery seeding machine in the fields. It can transplant onion seedlings, tomato seedlings, pepper seedlings, lettuce seedlings, cabbage seedlings and other seedlings.

There are three types of vegetable transplanters for sale available, respectively tractor-driven transplanting machine, crawler-type seedling transplanter and self-propelled transplanting machine. If you have a demand, come and contact us immediately. We’ll design the best solution and provide the best offer to you.

Type One: Tractor Driven Vegetable Transplanter

Tractor-driven vegetable transplanter machine integrates the functions of ridging, drip irrigation, filming covering, transplanting, and soil covering as a whole. This seedling transplanter machine has various models with different rows( 2-12 rows), and you can choose one based on your needs.

What you should pay attention to is that you should have a tractor before purchasing it. It is suitable for cucumber, eggplant, cabbage, pepper, sweet potato, and other economic crops.

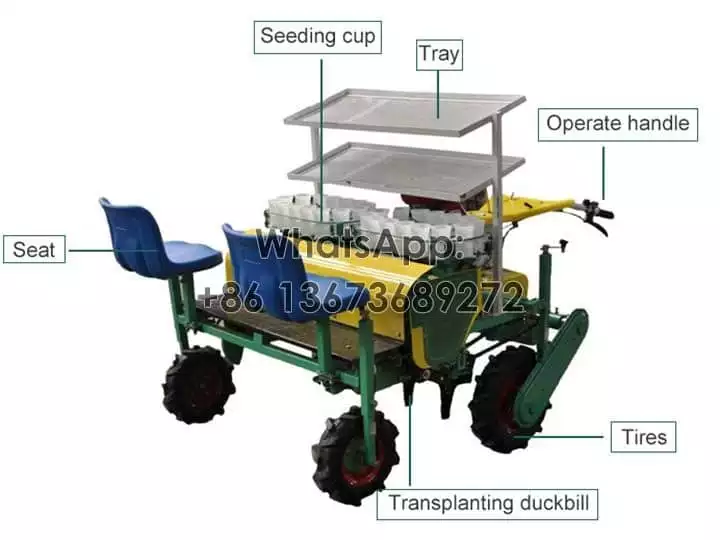

Structure of Automatic Vegetable Transplanter

This tractor-type mechanical vegetable transplanter has a very simple structure. It consists of trays for putting seedlings, PTO for connecting with the tractor, seedling cups for putting seedlings to transplant. Welcome to contact me for more information.

Technical Parameter of Vegetable Seedling Machine

From the below chart, we can well understand the clear data about transplanting various seedlings via the fully automatic vegetable transplanter. According to these data, you can basically know the seedling planter for tractor. If you want to know more, please get in touch with us immediately.

| Model | 2ZBX-2 | 2ZBX-4 | 2ZBX-6 | 2ZBX-8 | 2ZBX-10 | 2ZBX-12 |

| Plant spacing | 200-500mm | 200-500mm | 100-400mm | 100-400mm | 100-400mm | 100-400mm |

| Row spacing | 250-500mm | 250-300mm | 150-300mm | 150-300mm | 150-300mm | 150-300mm |

| Capacity | 1000-1700㎡/h | 1000-2700㎡/h | 1400-3400㎡/h | 2000-4000㎡/h | 2700-5400㎡/h | 3700-6700㎡/h |

| Row | 2 | 4 | 6 | 8 | 10 | 12 |

| Power | ≥30 | ≥50 | ≥60 | ≥60 | ≥60 | ≥60 |

Type Two: Self-propelled Transplanter Machine

Compared with tractor-driven type, self-propelled vegetable transplanter machine only can transplant seedlings without other functions such as ridging and film covering.

2-row seedlings planter

4-row vegetable seedling transplanter

It bears flexible steering and simple operation. Equipped with a gasoline engine, it is easy to move, and is suitable for mountainous and hilly areas.

In addition to this, we also have the latest 1-row manual vegetable transplanter, which uses a 5.5kw petrol engine, can be equipped with a watering function and is much more cost-effective. If you are interested, please contact us!

Structure of Semi Automatic Vegetable Transplanter Machine

This kind of seedling transplanter machine has a handle to operate. Also, it has the seat, seedling cups, trays, transplanting duckbill, wheels.

Technical Parameter of Hand-held Vegetable Transplanter

The vegetable seedling transplanter for sale can transplant seedlings for 2 rows or 4 rows. And it’s different in capacity and row spacing. You should choose the suitable rows to transplant based on your actual situation.

| Model | 2ZBZ-2 | 2ZBZ-4 |

| Plant spacing | 200-500mm | 200-500mm |

| Row spacing | 300-500mm | 150-300mm |

| Capacity | 1000-1400㎡/h | 1400-2000㎡/h |

| Row | 2 | 4 |

| Power | 4.05kw | 4.05kw |

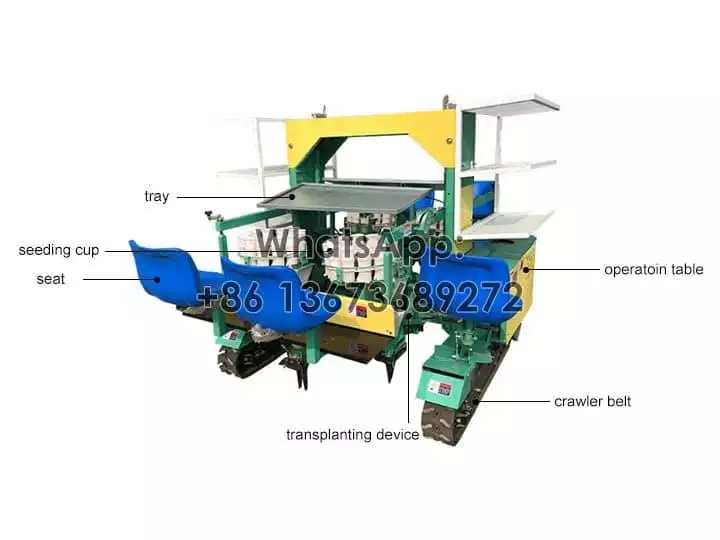

Type Three: Crawler Type Vegetable Transplanter

This crawler-type plug seedlings transplanter can transplant seedlings. Also, this machine can add film covering and drip irrigation.

Besides, this vegetable seedlings transplanter can transplant different rows (4-12 rows). This no till vegetable transplanter uses the gasoline engine as the power, commonly for onion, tomoto seedlings transplanting. Of course, the gasoline engine can change into the diesel engine. It depends on you.

During the operation, one person is only for driving the machine to move, while others are for putting the seedlings into seedling cups.

Structure of Fully Autoamtic Vegetable Transplanter

Compared to the above two transplanters, this vegetable seedling transplanter has the crawl belt, trays, seedling cups, seats, and transplanting system.

Technical Parameter of Autoamtic Transplanter

This type of seedling planter machine has clear data for your reference. The plant and row spacing can be adjusted within a certain range. If you have any doubt, please contact us for clarification.

| Model | 2ZBLZ-4 | 2ZBLZ-6 | 2ZBLZ-8 | 2ZBLZ-10 | 2ZBLZ-12 |

| Plant spacing | 200-450mm | 80-200mm | 80-200mm | 80-200mm | 80-200mm |

| Row spacing | 100mm | 150-200mm | 100-200mm | 150mm | 100-150mm |

| Row | 4 | 6 | 8 | 10 | 12 |

| Power | 4.05kW | 7.5kW | 7.5kW | 7.5kW | 7.5kW |

Importance of Using Vegetable Transplanter Machine

In many areas, due to the high labor intensity and low efficiency of manual transplantation, the row spacing and plant spacing after transplantation are uneven, which affects subsequent returns. In recent years, traditional agriculture has gradually transformed and upgraded.

With the growing maturity of seedling technology and rising labor costs, large-scale transplantation needs to be completed by seedling transplanter machine.

- Transplanting technology can make full use of light and heat resources, improve the yield of crops, and effectively avoid the adverse effects of low temperatures in early spring, frost, hail and other climates.

- It can avoid natural disasters such as pests and drought, increasing the survival rate of seedlings.

- Because the seedbed occupies less land, the seedlings are relatively concentrated, which makes it easy to manage seedlings in germination and seedling stages. The temperature of the seedbed can be controlled, boosting the quality of crops.

Operation Video of Vegetable Seedling Transplanter

The rotation of the crankshaft drives the movement of seedling inserting part that is consistent with the forward movement of the tractor. They rise and fall to ensure the seedlings can be inserted into the soil vertically.

You can replace the sprocket of the transmission mechanism to adjust the plant spacing. The horizontal seedling device is able to ensure sufficient transplanting time for seedlings, which effectively reduces the probability of missed seedlings, improving the transplanting efficiency.

Advantages of Seedlings Transplanting Machine

- Vegetable transplanter machine adopts advanced technology with a high survival rate without any damage to seedlings.

- The structure of the seedling transplanter machine is reasonable and the application range is wide. It can be used to transplant a variety of vegetables, fruits, tobacco, and other economic crops.

- It has stable performance and can plant seedlings in large areas.

- It is easy to adjust. Plant spacing can be customized according to your requirement, and the row spacing is adjustable.

- The transplanter machine adopts sprocket and chain transmission, and the planting distance is accurate.

- This machine greatly improves the quality of seedlings, greatly reducing the cost of transplanting. Meanwhile, the growth period of seedlings is consistent, which is convenient for field management.

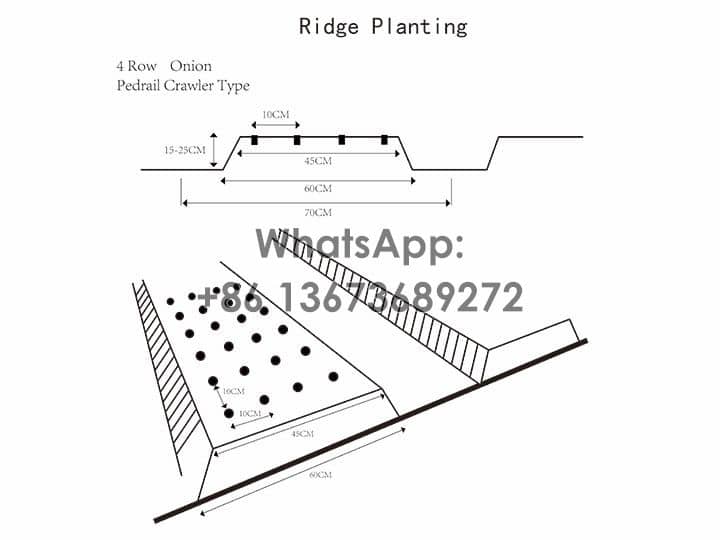

Things You Should Know When Transplanting Seedlings on Ridge

Because our vegetable transplanters can work on flat or ridged fields, you need to ask the customer whether they are transplanting on flat or ridged fields. If transplanting in ridges, you need to figure out the following data:

- Upper ridge width

- Bottom ridge width

- Ridge height

- Ridge furrow

- Row and plant spacing on the ridge

In fact, you can draw a diagram specifically for your client to make the data clearer.

Development of Transplanter Machine

In the 1980s, a semi-automatic vegetable planting machine was successfully developed. At the same time, a variety of transplanting machines is introduced to plant economic crops such as vegetables, tobacco, and sugar beets. However, these machine were not widely to the farmers due to unstable performance and low productivity.

In recent years, with the development of Taizy seedling technology, we have manufactured rather a mature seedling transplanting machine. Coupled with the emergence of new technologies and processes, it provides a good prospect for the development of transplanting machines.

Precautions When Using Vegetable Transplanter

- Before the vegetable transplanter enters the field, check whether the support wheel is in the transplanting state. Raise the two front legs and fix it with the bottom hole.

- When the transplanter enters the field, the tractor must move slowly while lowering the transplanter machine.

- The user should keep enough seedlings on the conveyor belt.

- When the transplanter machine turns around, stop placing the seedlings.

- The vegetable transplanter should move straight and uniformly.