This month, we exported a semi-automatic tomato seed sowing machine to Angola. This seedling machine helps our Angolan customers grow tomato seedlings in greenhouses, improving efficiency by 35% compared to manual seedling cultivation, with a germination rate of over 99.5%. Below are the details of the case.

Customer introduction

This customer from Angola is a greenhouse farmer specializing in economic crops such as tomatoes and chili peppers. The customer owns his own greenhouses, conducting multiple crop cycles year-round, thus placing high demands on seedling production efficiency and germination rates. The farm operates at a medium-to-large scale.

His requirements are:

During the seedling cultivation process, the customer aims to achieve automatic seeding functionality to reduce manual labor and enhance operational efficiency.

The customer emphasizes that the equipment should be reasonably priced, reliable in performance, and easy to maintain for daily use, ensuring convenient management of the seedling cultivation cycle and maintaining stability in bulk seedling production.

Taizy’s solution

Based on the customer’s situation, we recommended Taizy semi-automatic tomato seed sowing machine.

This equipment not only completes uniform seeding, but can also be customized according to the customer’s tray type to ensure compatibility and practicality.

The advantages of the semi-automatic nursery seedling machine include:

- High cost-effectiveness with low investment costs

- Simple operation requiring no specialized training

- Easy maintenance, suitable for daily use in greenhouse facilities

Finally, this Angola customer ordered KMR-78 nursery tray seeder and some nursery trays. List as below:

Nursery seedling machine

- Model: KMR-78

- Capacity: 200trays/hour

- Size: 1050*650*1150mm

- Weight: 68kg

- Material: carbon steel

- Matched with an air compressor

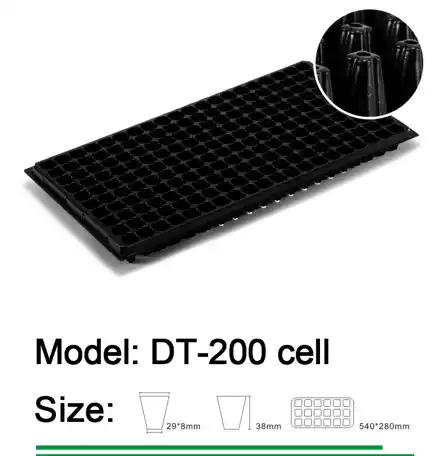

Nursery trays

- Model: 200 cells black tray

- Raw material: PVC

- Qty: 800pcs

- 100g per tray

- 200pcs per carton

Customer benefits

After using the semi-automatic seedling machine, the customer achieved a significant improvement in seedling production efficiency, enabling them to complete more seedling trays in a shorter time and significantly reduce labor costs.

The tomato seed sowing machine’s stability and ease of maintenance also helped the customer better manage the greenhouse seedling production cycle. It achieves efficient, continuous, and large-scale seedling production, providing ample and healthy seedlings for subsequent transplanting.