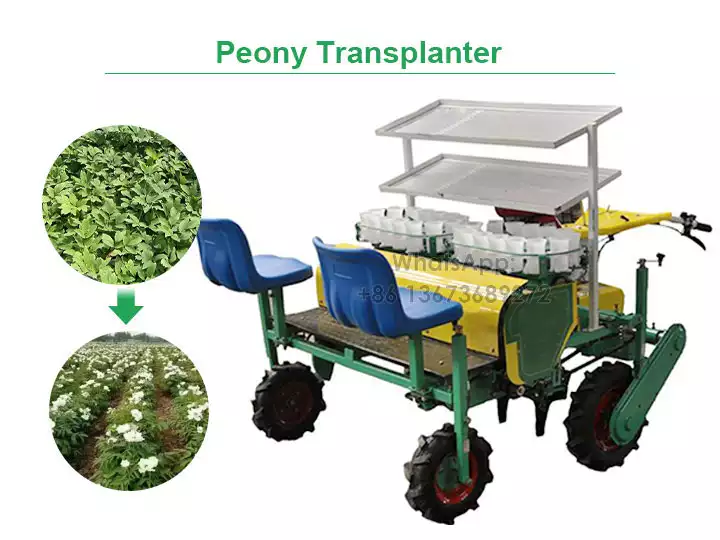

Peony transplanter is a particular machine used for transplanting peonies and is very popular in the Middle East. This is because flowers are prevalent in the Middle East. This peony transplanter machine can transplant peonies and cucumbers, onions, peppers, tomatoes, etc. However, the plant and row spacing are small because the transplanting machine has only 2 and 4 rows. Usually, we use the vegetable transplanter after the tray seedling machine completes working.

Also, you should note that this peony replanting machine uses a gasoline engine and is self-propelled, thus requiring manual control of the direction. If you have an interest, please feel free to contact us.

Applications of Peony Transplanting Machine

This machine is in the name of a peony transplanter, but in fact, it can transplant all kinds of fruits and vegetables and flowers. For example, pepper, tomato, cabbage, cucumber, pumpkin, okra, sweet corn, etc. If you have any questions, please feel free to contact us.

Advantages of Self-propelled Vegetable Transplanter

- It is equipped with a 4.05kW gasoline engine, which provides full power for automatic walking and transplanting.

- Wide range of applications. All kinds of fruits, vegetables, and flowers are available.

- Unique design, manual direction control, very user-friendly.

- Low damage rate to seedlings and high survival rate of transplanting.

- Long catching time, accurate and reliable catching of seedlings.

Working Principle of Seedling Transplanter

The peony transplanter machine utilizes a gasoline engine to generate power and control the operation of each part through the gearbox and clutch. Transmit the power generated by the engine to the spindle through the gearbox, and the spindle drives the driving wheel movement through the chain drive to drive the machine. Users can adjust the gears of the gearbox to achieve different driving speeds according to their needs.

Attention of Peony Planting Machine

- Thoroughly check the fasteners for looseness before operating the vegetable transplanter machine.

- When working, strictly forbid body parts to contact the rotating parts of the machine and prevent non-staff from approaching.

- When refueling the machine, no smoking and pay attention to fire prevention.

- Close the safety cover before starting the engine. And strictly forbid lifting or taking off the safety cover after starting.

- In order to make the machine can be safe and normal operation, do a good job of daily maintenance.